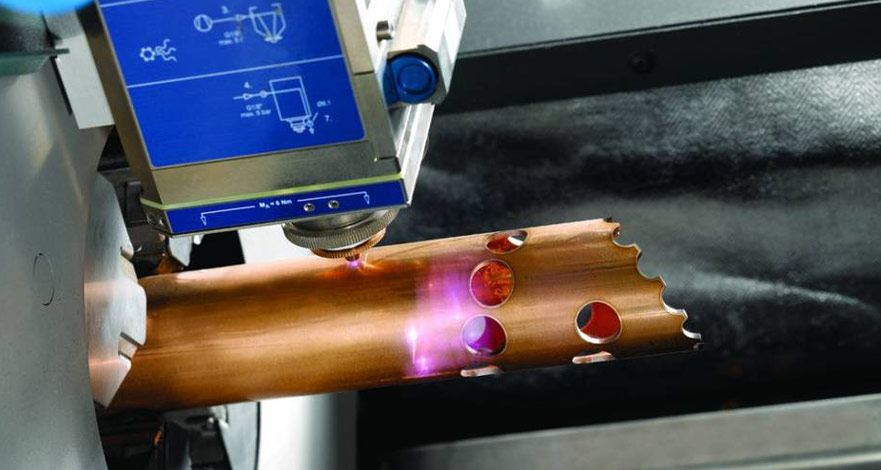

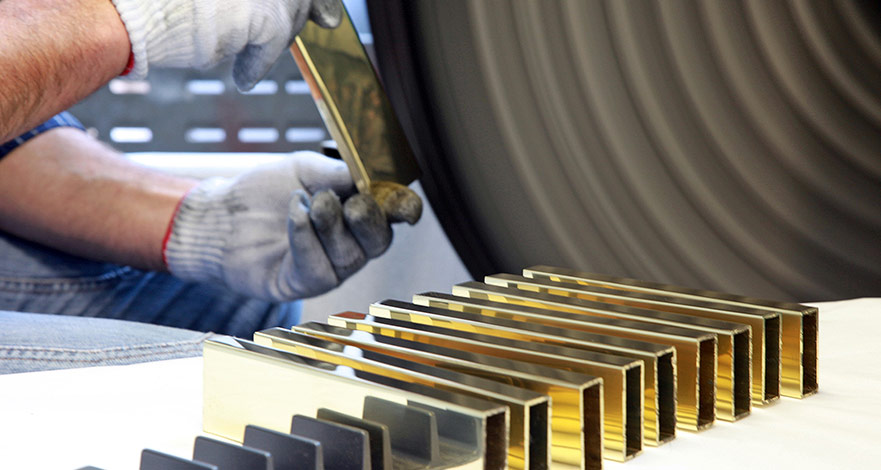

Giulipas production deals with a number of products, nevertheless tube processing remains the company’s core business. Over time, Giulipas has developed specific machines for optimised tube threading, drilling, bevelling and shearing.

These machines offer faster tooling and processing times, at the same time assuring zero damaging risks of the product surface following handling of pieces required for processing. Customers’ demands often go beyond this.

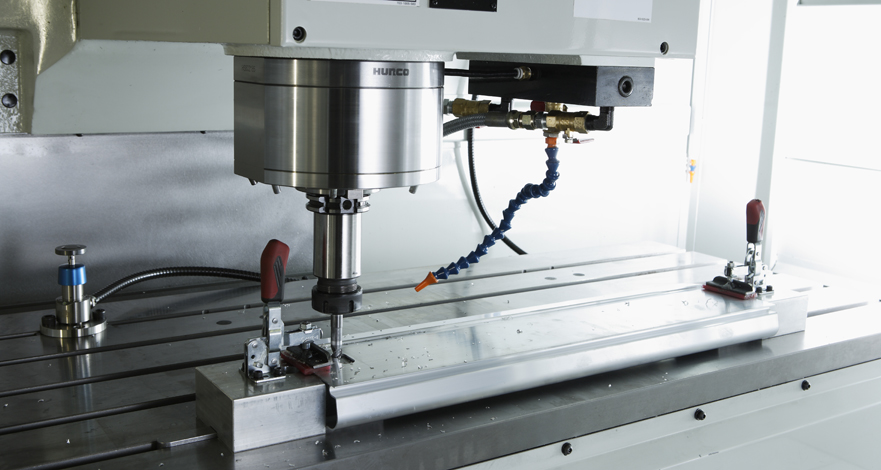

For years, Giulipas S.r.l. has availed itself of external suppliers, but recently it has revamped its machinery to carry out jobs in company. By doing so, all the needs pertaining to commonly requested product families can be met.