Most of the components made by Giulipas are intended for a last treatment aimed at improving their appearance and, at the same time, protecting the components themselves.

The most popular treatments are usually chrome-plating, painting and anodising.

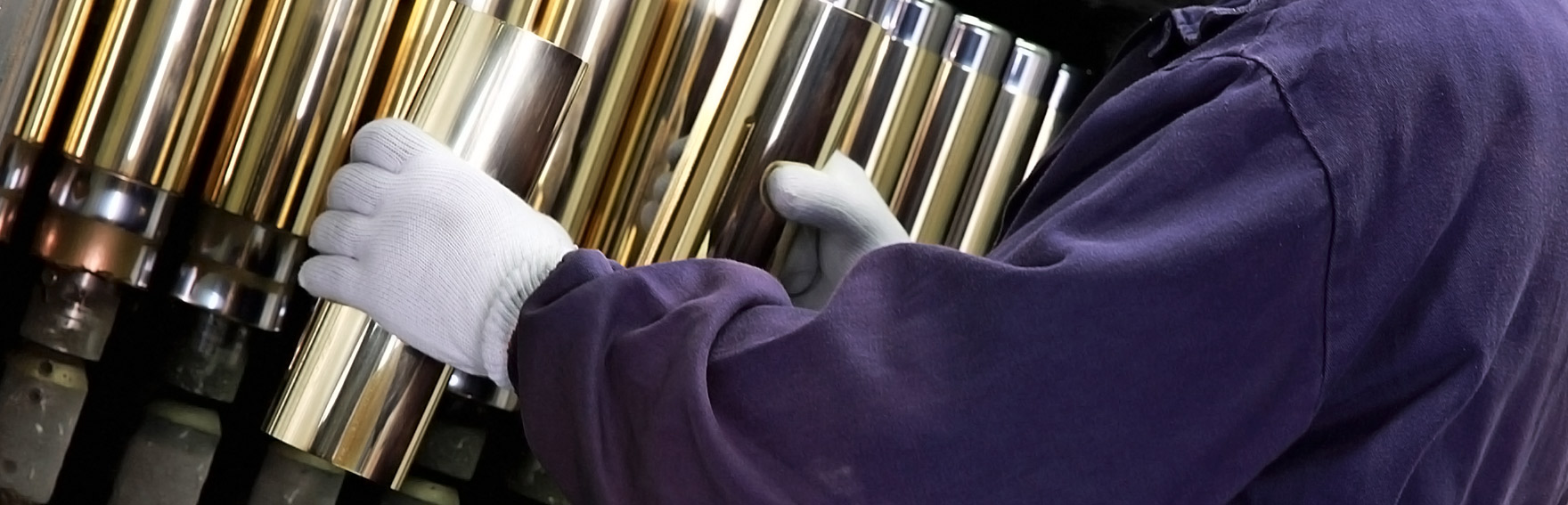

The chrome-plating treatment is by far the most popular one. Giulipas has relied on reliable and stable external companies for chrome-plating treatments for several decades now. Each partner possesses different skills and specifications, so that Giulipas is able to offer its own customers a wide range of products with chrome-plating treatments of extremely high quality: chrome-plated products in brass, aluminium, zamak and stainless steel, with dimensions that range from small parts up to tubes that are 3 metres long.

Chrome-plating is by far the most delicate stage of the piece production cycle. This is why Giulipas carries out very strict tests before and after the chrome-plating treatment. In addition, over the years packaging materials have also undergone a significant evolution, for the purpose of making the chrome-plating process more practical and, most importantly, for protecting the various components during handling.

With regards to painting and anodising, the request for these treatments is proportionally smaller, but also in this case Giulipas relies upon qualified external suppliers, guaranteeing their process control as wells as the quality of the resulting final product.