The machining of tubular profiles has always been Giulipas’ core business; however, along with this a new share has been conquered thanks to the introduction of a machining centre for mechanical finishing processes.

This investment was initially made by the company to meet the market need for special processes on tubes. The experience then acquired by Giulipas, including through training of its personnel, has made it possible to make even more complex products.

Nowadays, Giulipas usually also manages, for demanding customers, the production of die-casting moulds made of aluminium or zamak, relying upon long-standing suppliers. The moulds are sent to the proper foundries, always under the supervision of Giulipas. The pieces produced are then delivered to Giulipas’ facilities, where the various processes are carried out: milling, de-burring, threading, where required.

Generally speaking, the products have an aesthetic purpose, therefore it is crucial for Giulipas to carefully follow the mould design stage as well as the die-casting process since this is the starting point that allows a high-quality final product to be obtained.

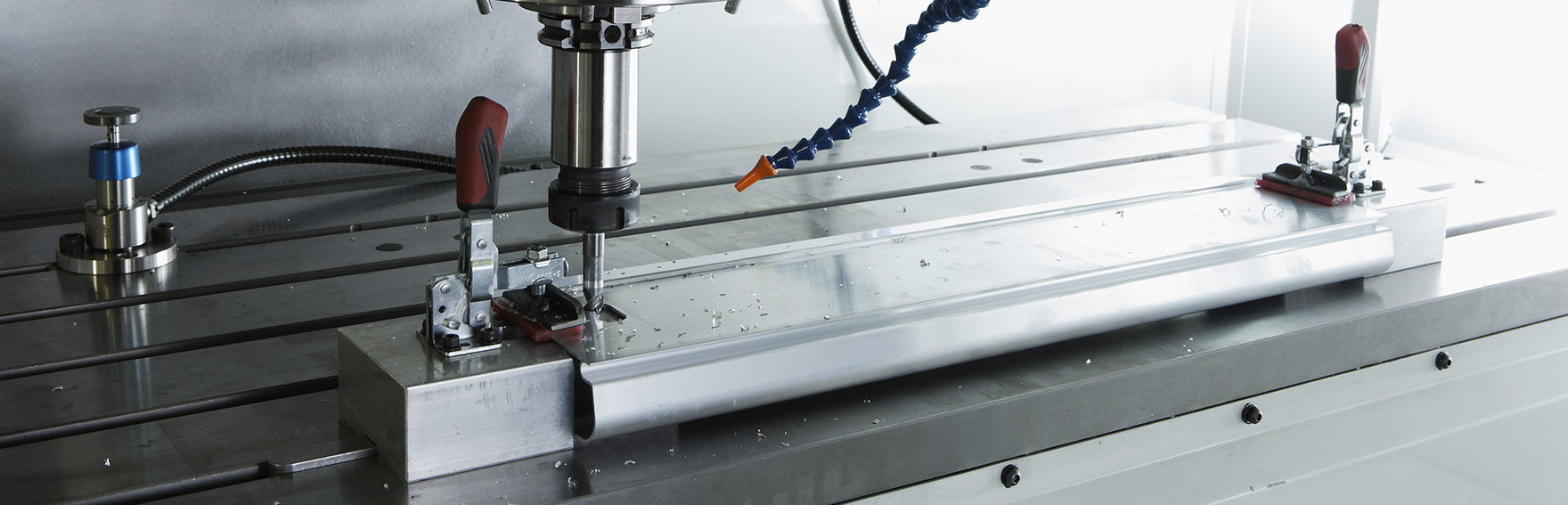

Again with a view to the final quality of the piece, the clamps used to secure the pieces onto the machining centres are of crucial importance, since they must be rigid enough without damaging the surfaces of the pieces which will then be exposed. This is the reason why the masks and clamps are designed and constructed in-company.

Once machining is carried out, a polishing or grinding stage usually follows, according to the customer’s request for that particular piece.